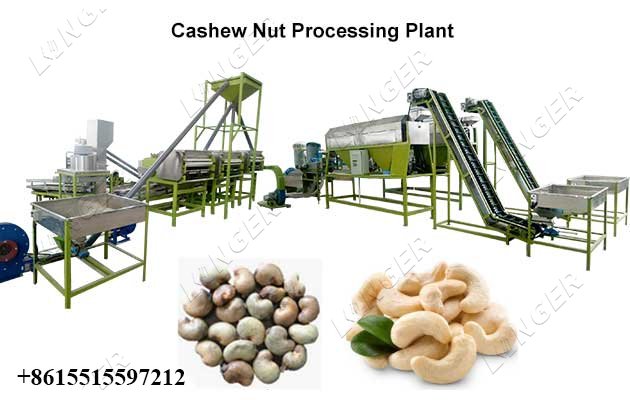

3 TPD Automatic Cashew Nut Shell Removing Machine

Capacity: 300 kg/h

Loading Port: Qingdao Port

Description: The cashew nut shell removing machine can complete the lifting, cutting, and shell kernel separation processes. Automatic shell breaking technology, high shelling efficiency.

Features

This cashew nut shell removing machine is a set of professional cashew nut processing equipment, which can cut and remove raw cashew nut shells. Automatic shelling technology, high cutting efficiency, shelling rate ≥98%, daily production capacity is 3T.

Introduction of the Cashew Nut Shell Remover Machine

The whole set of equipment includes a feeder, a hoist, three 6-knife cutting machine, a shell and kernel separator and a classifier, which mainly complete the shelling process of cashew nuts.

- One set of equipment can process two sizes of cashew nuts. (Conventional: one set of AB, one set of CD. CD is cashews below 20, 22-24 are AB cashews, over 24 are A+ cashews)

- The shells of cashew nuts of different sizes can be removed by adjusting the sheller.

- The part that touches the cashew kernel is made of 201 stainless steel.

- The production capacity is 300 kg/h.

Advantages of Automatic Cashew Shell Removing Machine

- Automatic shelling technology, no need to place materials, automatic blanking positioning,

- Multi-circuit and multi-channel separation and shelling for multiple times, high shelling efficiency and high removal rate.

- The part in contact with cashew nut kernels is made of stainless steel to ensure food safety.

- After cashew nuts are classified according to their size, the shelling rate can be increased to more than 98%.

- The equipped separation and sorting mechanism improves the separation and sorting efficiency of the nuts in the processing process, and improves the overall production efficiency of the whole line.

- It can be matched with cashew nut processing line, and the operation is simple.

The complete cashew nut processing process is:

Raw cashew grading - Steaming/cooking - Shelling - Separating the kernel and shell - Kernel drying - Kernel humidifying - Peeling - Kernel grading - Vacuum packing

Manual of Automatic Cashew Nut Shell Removing Machine

1. Adjust the distance between the upper and lower clamping blades according to the size of the cashew nut, and the distance between the clamping blades shall be less than 3-4mm of the width of the cashew nut.

2. Turn on the power supply and check whether the motor is rotating forward.

3. Put the cashew nuts into the hopper and start to work. Check whether the cashew nut kernel has any knife marks. If there are knife marks, adjust the height of the blade until there are no knife marks.

4. The blade of cashew nut shell remover is a vulnerable part and needs to be sharpened again after a period of use.

5. Regularly check the tightness of the chain. If the chain is too loose, the equipment will be damaged. The chain should be oiled once every 15 days.

6. Matters needing attention: Do not mix the raw materials with hard objects such as stones to prevent damage to the equipment.

Technical Data

| Capacity | 300kg/h |

| Total Power | 12kw |

| Dimension | 8000*6850*2600mm |

| Weight | 2000kg |

| Shelling Rate | 90%-98% |

0086-15515597212

0086-15515597212 serena@machinehall.com

serena@machinehall.com