Full Set Cashew Nut Milk Production Line 200 kg/h

Capacity: 200 KG/H

Loading Port: Qingdao Port

Description: The cashew milk production line includes a complete set of equipment from grinding to filling. Continuous processing, reasonable process, good quality cashew nut milk.

Features

The cashew milk production line includes a full set of equipment from cashew milk making to filling, mainly including grinding machine, screening machine, homogenizer and filling machine. The whole set of processing line has reasonable process design, realizes continuous production, and the finished cashew milk is of good quality.

This is also a multifunctional nut milk production line, which can also be used to produce tigernut milk, soy milk, almond milk, etc.

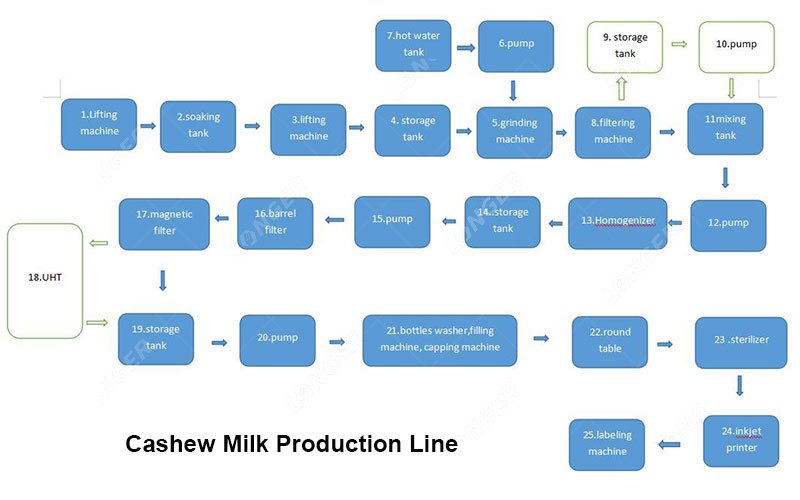

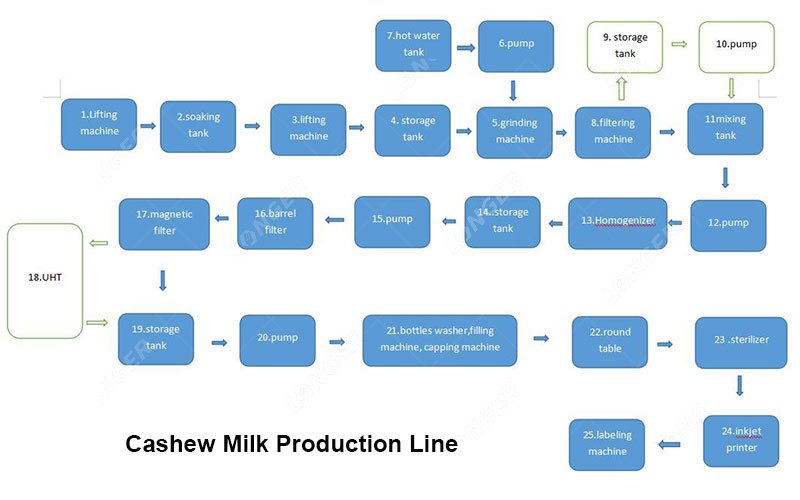

Cashew Nut Milk Production Process:

Lifting - Storage - Grinding - Screening - Stirring - Homogenizing - Temporary Storage - Filling - Sterilization - Coding - Labeling

1. Storage: Store the soaked cashews in a tank until processing.

2. Grinding: Pour water and cashews into a colloid mill and grind. Cashew nuts are effectively emulsified, dispersed, homogenized and pulverized to achieve the effect of ultra-fine pulverization and emulsification of materials, and cashew nut milk is obtained.

3. Screening: There will be residues in the ground milk, put it into the screening equipment to screen out the residues.

4. Stirring: The cashew nut milk is pumped into the heating stirring tank for heating.

5. Homogenization: The cashew milk is then put into a homogenizer for homogenization and refinement.

6. Temporary storage: The homogenized cashew milk is transported to the finished product tank by a pump for filling.

7. Filling: Fill the processed cashew milk into bottles one by one. The whole process is automatic and precise filling.

8. Sterilization: Sterilize the filled cashew milk. After the sterilization is completed, the shelf life effect is better.

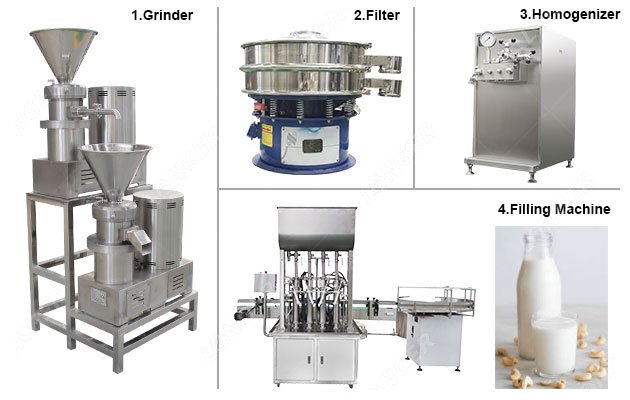

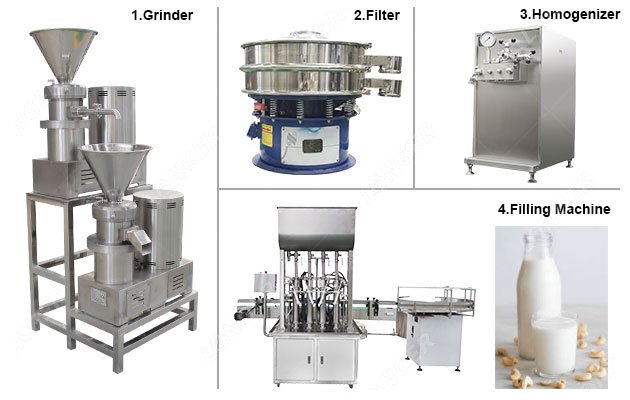

Core Equipment in the Cashew Milk Production Line:

1. Cashew Milk Grinding Machine

It is a colloid mill that can grind nuts, fruits and vegetables and other materials. It can effectively emulsify, disperse, homogenize and pulverize materials, and is usually used to make nut butter or nut milk.

Its main parts are made of stainless steel, which is corrosion-resistant and non-toxic. According to the characteristics of different materials, the production efficiency is different. By adjusting the gap between the stator and the rotor, the particle size of the finished product is adjusted.

2. Filter Screening Machine

It is a high-precision screening machine with low noise, high screening accuracy and high efficiency. Fully enclosed structure, suitable for screening and filtration of powder, mucus and other materials. The screen can be used for a long time, the screen is easy to change, it only takes 3-5 minutes, and the operation is simple.

3. Cashew Nut Milk Homogenizer

This is a high pressure homogenization and emulsification equipment. High-pressure homogenization of cashew milk has many advantages: high stability, reduced stratification, improved preservation quality, faster reaction time, and savings in additives. The fat globules in the homogenized cashew milk are significantly refined, which is easier to digest and absorb, improves the edible value, and greatly improves the taste.

4. Cashew Milk Filling Machine

The filling machine is under the operation and control of high-speed PLC, through the man-machine dialogue interface, to realize linear stepless speed regulation conveying, and the filling capacity can be adjusted arbitrarily. The filling machine integrates machine, electricity and gas, with unique design, complete functions, stable performance, good quality and beautiful appearance.

The above is the introduction of the entire cashew milk processing line, if you are interested, please contact us.

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

This is also a multifunctional nut milk production line, which can also be used to produce tigernut milk, soy milk, almond milk, etc.

Cashew Nut Milk Production Process:

Lifting - Storage - Grinding - Screening - Stirring - Homogenizing - Temporary Storage - Filling - Sterilization - Coding - Labeling

1. Storage: Store the soaked cashews in a tank until processing.

2. Grinding: Pour water and cashews into a colloid mill and grind. Cashew nuts are effectively emulsified, dispersed, homogenized and pulverized to achieve the effect of ultra-fine pulverization and emulsification of materials, and cashew nut milk is obtained.

3. Screening: There will be residues in the ground milk, put it into the screening equipment to screen out the residues.

4. Stirring: The cashew nut milk is pumped into the heating stirring tank for heating.

5. Homogenization: The cashew milk is then put into a homogenizer for homogenization and refinement.

6. Temporary storage: The homogenized cashew milk is transported to the finished product tank by a pump for filling.

7. Filling: Fill the processed cashew milk into bottles one by one. The whole process is automatic and precise filling.

8. Sterilization: Sterilize the filled cashew milk. After the sterilization is completed, the shelf life effect is better.

Core Equipment in the Cashew Milk Production Line:

1. Cashew Milk Grinding Machine

It is a colloid mill that can grind nuts, fruits and vegetables and other materials. It can effectively emulsify, disperse, homogenize and pulverize materials, and is usually used to make nut butter or nut milk.

Its main parts are made of stainless steel, which is corrosion-resistant and non-toxic. According to the characteristics of different materials, the production efficiency is different. By adjusting the gap between the stator and the rotor, the particle size of the finished product is adjusted.

2. Filter Screening Machine

It is a high-precision screening machine with low noise, high screening accuracy and high efficiency. Fully enclosed structure, suitable for screening and filtration of powder, mucus and other materials. The screen can be used for a long time, the screen is easy to change, it only takes 3-5 minutes, and the operation is simple.

3. Cashew Nut Milk Homogenizer

This is a high pressure homogenization and emulsification equipment. High-pressure homogenization of cashew milk has many advantages: high stability, reduced stratification, improved preservation quality, faster reaction time, and savings in additives. The fat globules in the homogenized cashew milk are significantly refined, which is easier to digest and absorb, improves the edible value, and greatly improves the taste.

4. Cashew Milk Filling Machine

The filling machine is under the operation and control of high-speed PLC, through the man-machine dialogue interface, to realize linear stepless speed regulation conveying, and the filling capacity can be adjusted arbitrarily. The filling machine integrates machine, electricity and gas, with unique design, complete functions, stable performance, good quality and beautiful appearance.

The above is the introduction of the entire cashew milk processing line, if you are interested, please contact us.

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Technical Data

| No. | Name | Size(mm) | Qty(set) |

| 1 | Grinding Machine | 810*760*1300 | 2 |

| 2 | Filtering Machine | 800*800*890 | 1 |

| 3 | Mixing Machine | 800*1355 | 1 |

| 4 | Homogenizer | 1030*745*990 | 1 |

| 5 | Mixing Tank | 800*1355 | 2 |

| 6 | Filling and Capping Machine | 1600*1450*2200 | 1 |

Related Cashew Machine

0086-15515597212

0086-15515597212 serena@machinehall.com

serena@machinehall.com