Automatic Cashew Butter Paste Production Line LONGER

Capacity: 150-200 kg/h

Loading Port: Qingdao Port

Description: This automatic cashew butter production line can realize the continuous processing of cashew paste. It can produce original cashew butter, seasoned cashew butter, crunchy cashew butter, etc.

Features

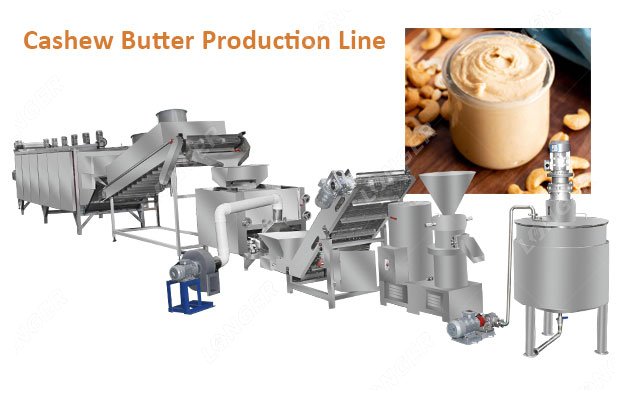

This is a set of automatic cashew butter production line, which can realize the continuous processing of cashew nuts, from roasting to cashew paste filling. This set of machinery can make original cashew butter, flavored cashew butter, etc. Streamline operation, efficient and stable operation, and high reliability.

Working flow of cashew paste production line:

Roasting -- Cooling -- Cashew Butter Grinding -- Storage -- Mixing -- Degassing -- Filling

Introduction of Cashew Butter Production Line

The equipment that composes the cashew butter production line is: roasting machine, cooling belt, picking belt, cashew paste grinder, paste cooler, mixing tank, degassing tank, filling machine.

(1) Cashew nut roasting machine: continuous roasting of cashew nuts, with separate gas heating and electric heating, uniform roasting and automatic temperature control. Fast temperature rise and stable performance.

(2) Cooling belt: Use the principle of the fan to extract the hot air to cool the roasted cashews and quickly cool them.

(3) Picking belt: manually picking unqualified cashews to ensure the quality of the finished sauce.

(4) Cashew paste grinder: Grind the roasted cashews to obtain cashew paste. By adjusting the gap between the two grinding bodies, the fineness of the cashew paste can be adjusted to 100 mesh.

(5) Sauce cooler: cool the grinded cashew butter. Quickly cool the sauce to prevent the long-term high temperature from changing the color and composition of the sauce, which will affect the appearance and taste.

(6) Degassing tank: Vacuum degass cashew paste before filling to inhibit browning, oxidation of pigments, vitamins, aroma components and other substances, and prevent quality degradation.

(7) Filling machine: filling and packaging. The filling volume can be adjusted to achieve precise filling results.

Application of Automatic Cashew Paste Production Line

This equipment can not only make cashew butter, such as raw cashew butter, flavored cashew butter, crunchy cashew butter, etc. Other nut butters can also be made, such as peanut butter, almond butter, pistachio butter, macadamia butter, etc.

The specific process flow and output can be customized according to customer requirements.

If you need it, welcome to inquire:

Email: serena@machinehall.com WhatsApp: +8615515597212

Technical Data

| No. | Name | Power(kw) | Size(mm) |

| 1 | Cashew roasting machine | 70 | 6000*1500*1450 |

| 2 | Continuous cooling machine | 8 | 6000*800*2600 |

| 3 | Screening belt | 0.75 | 5000*800*1000 |

| 4 | Cashew butter grinder | 11*2 sets | 1000*350*900 |

| 5 | Storage tank | 200L | |

| 6 | Paste pump | 1.5 | 1200*300*350 |

| 7 | Mixing tank | 2.2 | 300L |

| 8 | Vacuum degassing tank | 2.2 | 300L |

0086-15515597212

0086-15515597212 serena@machinehall.com

serena@machinehall.com